Advanced Search

iCVD synthesis protocol

Last updated date: Nov 10, 2024 Views: 66 Forks: 0

Email: pc688@cornell.edu; ryang@cornell.edu

Affiliation: Robert Frederick Smith School of Chemical and Biomolecular Engineering, Cornell University, Ithaca, NY, 14853, USA.

Materials and Reagents

Chemicals

General cleaning chemicals: Acetone, Ethanol, Deionized water.

Initiator: tert-Butyl peroxide (TBPO, 98%, Sigma-Aldrich)

Monomer: N-vinylimidazole (VI, 99%, Sigma-Aldrich)

Crosslinker: Divinylbenzene (DVB, 80%, Sigma-Aldrich)

Derivatization Reagent: 1,3-Propanesultone (98%, Sigma-Aldrich)

Carrier Gas: Argon gas (Ar, 99.999% purity)

Equipment

Custom-Built iCVD Reactor: Cylindrical vacuum reactor (Sharon Vacuum Co Inc.)

Filament Array: Nickel/chromium filament (80% Ni / 20% Cr, 0.5 mm diameter, Goodfellow)

Thermocouple and Feedback Loop: For monomer heating jar/chamber/filament temperature control

Deposition Stage: Temperature-controlled using a chiller

Mass Flow Controllers: For precise gas flow regulation

Butterfly Valve: For chamber pressure control

Substrates:

- Silicon wafers (P/Boron <100>, Purewafer)

- 96-well microplates (Corning 2797)

- Glass slides (Thermo Fisher Scientific)

- Petri dishes (Thermo Fisher Scientific)

- Copper foil (MTI Corporation)

- PVC sheets (McMaster-Carr)

- Glass fiber filters and polycarbonate membrane filters (Sigma-Aldrich)

Customized Aluminum Holder: For enhanced cooling of microplates

HeNe Laser Source: For in situ interferometry (wavelength = 633 nm, JDS Uniphase)

Vacuum Oven: For post-deposition derivatization (VWR)

Procedure

1. Preparation of the iCVD Reactor System

- Clean the iCVD reactor chamber using isopropanol and razor blade.

- Mount the 0.5-mm nickel/chromium filament as a parallel array on a customized holder inside the chamber, maintaining a vertical distance of ~2 cm from the deposition stage.

- Attach a thermocouple to middle of the filament arrays for temperature monitoring control.

- Precooling the deposition stage using a chiller to maintain the substrate temperature at 35℃.

- Preheating the monomer jars containing N-vinyl imidazole to 70℃ and divinylbenzene to 65℃ using a customized heating jacket to generate sufficient vapor pressure.

- Ensure that the mass flow controllers and butterfly valve are functioning properly to regulate gas flow and chamber pressure.

2. Substrate Preparation

- Clean the substrates (i.e., Si wafers and glass slides) using acetone, ethanol and deionized water and dry it with N2.

- Place the substrates onto the cooled deposition stage.

For 96-well microplates, use a custom-designed aluminum holder for enhanced cooling. No pre-cleaning procedure is needed.

3. Deposition Process

- Evacuate the reactor chamber to a base pressure of <5 mTorr with leak rate lower than 0.1 sccm.

- Calibrate the flow rates for TBPO, VI and DVB as desired value. The deposition condition was summarized as follows:

Material | F(1VI) (sccm) | F(DVB) (sccm) | F(TBPO) (sccm) | F(Ar) (sccm) |

P1VI | 1.65 | 0 | 0.6 | 0.85 |

CP55 | 1.55 | 0.10 | 0.6 | 0.85 |

CP26 | 1.45 | 0.20 | 0.6 | 0.84 |

CP17 | 1.32 | 0.34 | 0.6 | 0.84 |

PDVB | 0 | 1.68 | 0.6 | 0.82 |

3. When the chamber pressure reaches 500 mTorr, set the filament temperature to 230°C using the DC power supply to initiate the reaction.

4. Film Growth Monitoring

- Use in situ interferometry with a HeNe laser (633 nm) to monitor film growth on a Si substrate. Observe the intensity of the reflected laser to track the thickness in real-time.

5. Derivatization of Coating

- After the iCVD deposition, transfer the coated substrates to a crystallizing dish (VWR).

- Add 1 g of 1,3-propanesultone to the dish.

- Use Al foil to seal the crystallizing dish.

- Place the crystallizing dish inside a vacuum oven and maintain it at the desired temperature (e.g., 40, 60 and 100℃**) for 24 hours under vacuum to allow the vapor-phase reaction of 1,3-propanesultone with the PVI-co-DVB coating.

6. Post-Treatment and Cleaning

- Remove the substrates from the vacuum oven and rinse them with DI water to remove any unreacted 1,3-propanesultone and un-crosslinked polymers.

- Dry the substrates under a stream of nitrogen gas.

7. Characterization of Coating

- Use Fourier-Transform Infrared Spectroscopy (FTIR) to confirm the chemical composition of the coatings. Look for characteristic peaks of imidazole and the sulfonate group (S=O, S-O- stretch) after derivatization.

- Measure the film thickness using ellipsometry or profilometry.

- Evaluate the surface properties (e.g., wettability) using a contact angle goniometer.

- Analyze the chemical composition and gradient profile using X-ray Photoelectron Spectroscopy (XPS).

Data Analysis

Calculate the deposition rate using the film thickness:

![]()

Where:

-![]() : Change in film thickness (measured by ellipsometry) (nm)

: Change in film thickness (measured by ellipsometry) (nm)

-![]() : Deposition time (min)

: Deposition time (min)

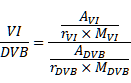

Confirm the polymer composition

Where:

-![]() : Featured peak area

: Featured peak area

-![]() : Featured peak area normalized by thickness obtained on homopolymer thin film

: Featured peak area normalized by thickness obtained on homopolymer thin film

-![]() : Molecular weight of monomer

: Molecular weight of monomer

Related files

Protocol.docx

Protocol.docx - Chen, P and Yang, R(2024). iCVD synthesis protocol. Bio-protocol Preprint. bio-protocol.org/prep2751.

- Chen, P., Lang, J., Zhou, Y., Khlyustova, A., Zhang, Z., Ma, X., Liu, S., Cheng, Y. and Yang, R.(2022). An imidazolium-based zwitterionic polymer for antiviral and antibacterial dual functional coatings. Science Advances 8(2). DOI: 10.1126/sciadv.abl8812

Do you have any questions about this protocol?

Post your question to gather feedback from the community. We will also invite the authors of this article to respond.

Share

Bluesky

X

Copy link