- EN - English

- CN - 中文

A Protocol Guide to Micro Milling for Bio-Microfluidics

生物微流控用微铣削实验方案指南

(§Technical contact: hviola@umich.edu) 发布: 2025年10月05日第15卷第19期 DOI: 10.21769/BioProtoc.5459 浏览次数: 1350

评审: Joyce ChiuSrestha DasguptaAnonymous reviewer(s)

Abstract

Micro milling is a subtractive manufacturing method for fabricating micro-scale three-dimensional features from hard substrates like acrylic, wood, or metal. It enables rapid prototyping of biomicrofluidic devices and master molds, offering advantages over traditional fabrication methods like photolithography. Micro milling is seldom applied in the fabrication of organs-on-a-chip, in part due to its requirement for knowledge of computer numerical machining techniques that are required to program and operate micro mills. This protocol provides practical guidelines for micro milling–based fabrication of organs-on-a-chip, including toolpath optimization, SolidWorks and Fusion workflows, and troubleshooting tips. A case study demonstrates the design and fabrication of master molds for a human airway-on-a-chip, validated in a recent publication. This resource supports the expansion of micro milling techniques into organs-on-a-chip, which will enhance capacity for rapid device prototyping and design of more complex 3D features that better recapitulate human physiology.

Key features

• Stepwise guide to lung-on-a-chip design and fabrication via micro milling, a specialized type of computer numerical control (CNC) machining.

• Demonstration of model design, tool path optimization, micro milling, device assembly, and cell culture.

• Example SolidWorks and Fusion documents illustrating best practices for model design and toolpath generation.

Keywords: Microfluidics (微流控)Background

Rapid micromachine prototyping helps optimize biomicrofluidic devices to culture organoids, generate particles, and create organs-on-a-chip. Environments such as university or community-led “makerspaces” have expanded access to micromachining equipment, such as computer numerical control (CNC) machines and 3D printers, for rapid prototyping. Micro milling, in particular, is well suited to microfluidics for biomedical applications (i.e., biomicrofluidics) [1]. This technique is inexpensive, provided that the capital investment in a micro mill has been met, and is rapid and flexible in its capabilities. Micro mills are CNC machines that execute a computer-designed path to make precision cuts via subtractive manufacturing. Micro mills differ from traditional CNC mills in that they operate at the millimeter-to-submicron scale, whereas traditional CNC machining centers work at a macroscopic scale. Therefore, micro milling has been utilized to fabricate microfluidic devices, including those with biomedical applications where rapid prototyping is desirable [2]. However, sparse resources exist to introduce micro milling technology to biomedical researchers who might benefit from its advantages in biofabrication. Here, we provide a step-by-step protocol describing lung-on-a-chip microfluidic device design, fabrication, and cell culture. Techniques described herein are broadly applicable to organ-on-a-chip design and fabrication with micro mill technology.

Micro milling is advantageous for the fabrication of certain microscale features in a relatively quick and low-cost fashion compared to other manufacturing methods. Compared to traditional photolithography, micro mills can more readily fabricate three-dimensional curved shapes and handle low width-to-height aspect ratio features. Additionally, traditional photolithography-coupled soft lithography is limited to ~100–200 μm depth and two-dimensional features [2]. Micro milling eliminates the need to generate a lithography mask for each new design, which lowers the number of fabrication steps required for quicker iteration. Furthermore, CNC-based micro milling needs little supervision once set up and does not require a cleanroom. However, micro milling is disadvantageous at the lower nanoscale compared to photolithography. Additionally, micro milling cannot necessarily perform undercuts and has limitations to the radius of curvature that can be achieved on inside corners. Finally, micro-milled surfaces tend to have a greater surface roughness than comparable surfaces created by photolithography-coupled soft lithography, which could affect cell viability [2] and surface adhesiveness.

In comparison to 3D printing, micro milling is compatible with harder substrates that are difficult to extrude, such as wood, ceramic, and metal, for durable master mold generation. Additionally, a direct comparison of micro milling of acrylic vs. 3D printing of UV-curable substrate to fabricate the same features found that micro-milled square channels had a smoother surface finish and more defined side walls with greater feature accuracy [3]. Additionally, z-axis resolution is limited in most 3D printing situations, so that at the microscale, noticeable ridging can occur on curved surfaces [4]. Micro mills are uniquely suited to fabricate curved features without this artifact. However, for larger-scale (micron to centimeter) designs requiring bioprinting, overhangs, or channels passing over or under one another, 3D printing is most appropriate [5,6]. Polymer parts are also fabricated by injection molding, which has demonstrated precision and desirable reproducibility [7]. However, for pilot studies that are typical of rapid prototyping applications, micro milling is substantially more economical, as injection molding requires a costly start-up investment in custom molds that are designed for repeated long-term use. Alternatively to machining, microscale features are also fabricated by laser techniques and piezoelectric rather than mechanical mills; however, the aforementioned accessibility and ubiquity of milling equipment makes it desirable in microfluidic prototyping, especially for the creation of a master mold that can be cast to create poly(dimethylsiloxane) (PDMS) devices (Figure 1) or for directly making final parts out of hard plastics when the microfluidic systems deal with small sample sizes such as in scRNAseq-on-a-chip or PCR-on-a-chip to prevent absorption of analytes into PDMS. The overall balance of micro milling’s advantages vs. limitations should be taken into account in the determination of its appropriateness for a particular application. For examples of the application of micro milling in biology, we document several recent works and their milling parameters, as available, in Table 1 below.

Table 1. Example biomicrofluidics and manufacturing parameters

| Citation | Material | Application | End mill (s) | Spindle speed | Feed rate | Depth of cut/ stepdown | Manual stepover |

|---|---|---|---|---|---|---|---|

| [8] Viola 2024 | Acrylic | Nanoinjector | 500 μm flat 200 μm ball | 10,000 rpm 30,000 rpm | 25.53 mm/min 12.27 mm/min | 0.25 mm 0.10 mm | 0.125 mm 0.050 mm |

| [9] | Acrylic | Bladder on a chip | 3 μm carbide flat | Not reported | Not reported | Not reported | Not reported |

| [10] | Poly(methyl methacrylate) (PMMA) | Microfluidic vascular model with integrated electrodes | 254 μm | Not reported | Not reported | 175 μm | Not reported |

| [11] | PMMA | Tumor spheroid device | 1 mm carbide square 2-flute | 18,000 rpm | 60 mm/min | 100 μm | Not reported |

| [12] | Polystyrene | Macrophage culture on chip | Not reported | Not reported | Not reported | Not reported | Not reported |

| [13] | Aluminum | Spiral-shaped test device | 200 μm | 10,000–20,000 rpm | 50–150 mm/min | 5 μm | Not reported |

| [14] | PMMA | Test device with curved channels | 350 μm 2 flute steel | 4,000 rpm | 10 mm/min | 0.5 mm | Not reported |

| [15] | Brass | DNA gel electrophoresis | 500 μm carbide 200 μm carbide 100 μm carbide 50 μm carbide | 40,000 rpm | 200 mm/min 100–150 mm/min 50–75 mm/min 10–20 mm/min | Not reported | Not reported |

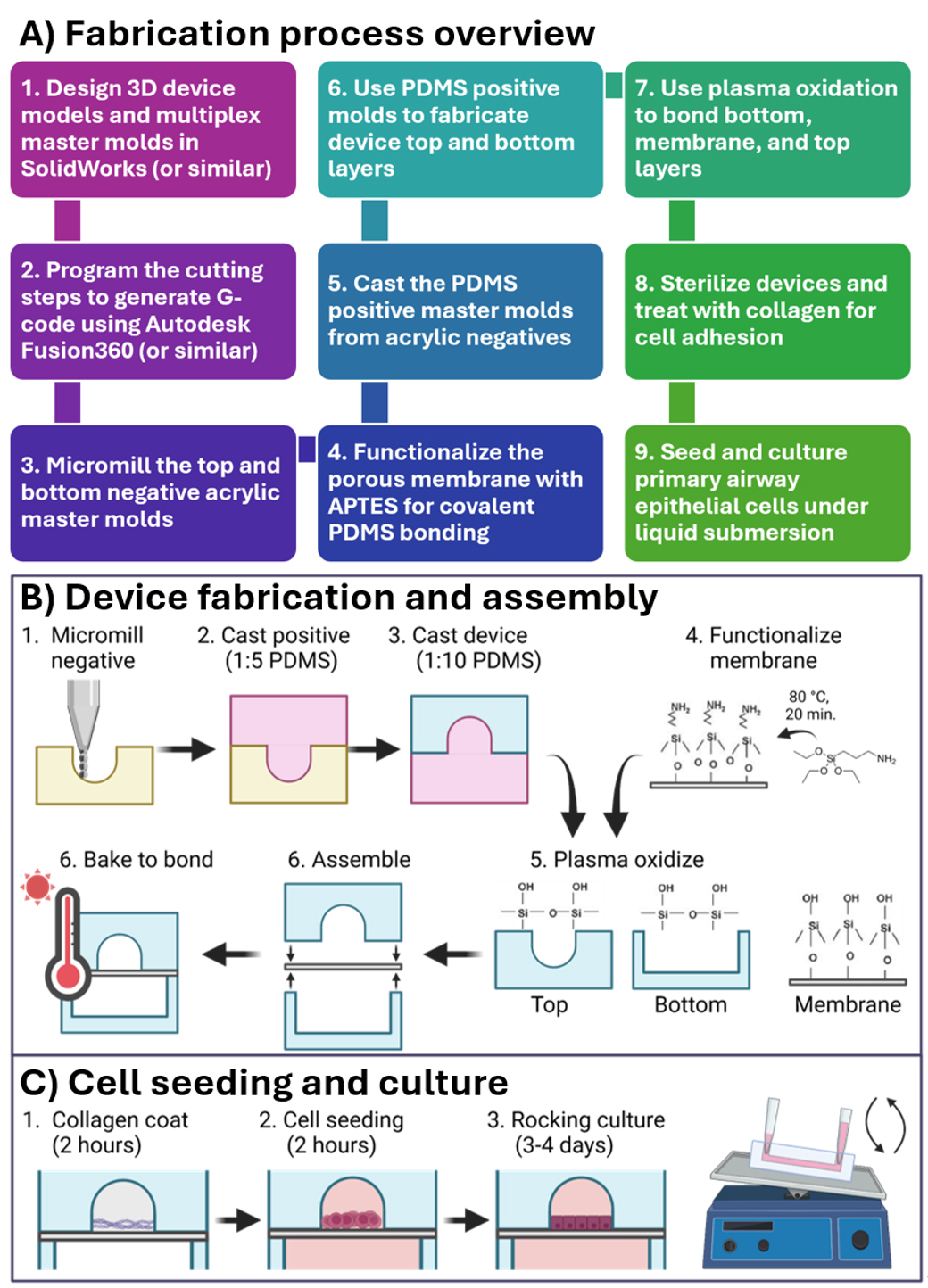

Figure 1. Protocol steps described herein. (A) An overview of the fabrication steps for a micro-milled organ-on-a-chip that are described in this protocol. (B, C) Illustrations of protocol steps as published in Viola [8] Lab on a Chip. This figure is reproduced from our article in Lab on a Chip available at https://pubs.rsc.org/en/content/articlelanding/2024/lc/d3lc00957b. This figure is reprinted under Clause 3.2 of the Copyright Owner(s)’ Rights under the Royal Society of Chemistry’s License to Publish Agreement.

Materials and reagents

Biological materials

1. SAEC, human small airway epithelial cells (Lonza, catalog number: CC-2547)

Reagents

1. SAGMTM Small Airway Epithelial Cell Growth Medium BulletKit® (Lonza, catalog number: CC-3118)

2. ReagentPackTM subculture reagents, 100 mL (Lonza, catalog number: CC-5034)

3. Corning® Collagen I, rat tail, 100 mg (Corning, catalog number: 354236)

4. (3-Aminopropyl) triethoxysilane (APTES) (Millipore Sigma, catalog number: 440140-100ML)

5. Dowsil Slygard 184 Silicone Elastomer kit 0.5 Kg (1.1 lb) clear (Dow Chemical, Krayden, Manufacturer: dc4019862; Vendor: 4019862)

6. UltraPureTM DNase/RNase-free distilled water (or equivalent) (ThermoFisher, catalog number: 10977015)

7. 1 M sodium hydroxide (Sigma Aldrich, CAS number: 1310-73-2)

8. DPBS, no calcium, no magnesium (ThermoFisher Scientific, Gibco, catalog number: 14190250)

Laboratory supplies

1. 24 in. × 48 in. × 0.250 in. clear acrylic sheet (4 per pack) (Home Depot, PlexiGlass, model: MC2448250)

2. CorningTM TranswellTM multiple well plate with permeable polycarbonate membrane inserts, 0.4 μm pore size, for 6-well plates (Fisher Scientific, catalog number: 07-200-165, CorningTM, catalog number: 3412)

3. 1,000 μL pipette tips, no filter, sterile (ThermoFisher, catalog number: 9401113)

4. 200 μL pipette tips, with filter, sterile (Corning Millipore Sigma, catalog number: CLS4823-960EA)

5. NuncTM Square BioAssay dish, 25 mm non-treated (ThermoFisher, catalog number: 240835)

6. Single edge razor blades (ULINE, catalog number: H-595B)

7. Cole-Parmer low-form beaker, glass, griffin style, graduated, 400 mL; 8/Pk (Cole-Parmer, model: UX-34502-45)

8. USA Lab rare earth magnet pill-shaped stir bars, various sizes (USALAB, SKU: REP-8x22)

9. Labeling tape, white, W × L 3/4 in. × 500 in. (Sigma-Aldrich, catalog number: Z768294)

10. Extra Fine Graefe forceps (Fine Science Tools, catalog number: 11150-10)

11. 10 mL/cc syringes with 18Ga needles and caps, disposable syringe, single sterile individually packaged (20Pack-10ML) (Premium Vials, SKU: B07DVXPNKT)

12. FisherbrandTM high precision metal scalpels (Fisher Scientific, catalog number: 08-920B)

13. Self-healing cutting mat, 24 × 18", blue (ULINE, catalog number: S-18545)

14. Grip-NTM hot mill gloves (ULINE, catalog number: S-19220)

15. Aluminum foil roll, heavy-duty, 24" × 500' (ULINE, catalog number: S-22910)

16. 1.88 in. × 54.6 yds. Heavy-duty shipping packaging tape with dispenser (The Home Depot, Scotch Brand, #100149185, model: 3850-RD-DC, Store SKU #545597)

17. 3 M 667 Scotch® double-sided tape with dispenser, 3/4" ×11 yds (ULINE, Scotch Brand, catalog number: S-18907)

18. Integra Lifesciences disposable standard biopsy punches, disposable biopsy punch with plunger, 1.5 mm, 33-31A-P/25 (Grayline Medical, by Integra Lifesciences Corp, SKU: 33-31A-P/25)

19. MilliporeSigmaTM SteriflipTM sterile disposable vacuum filter units, 0.22 μm (Fisher Scientific, catalog number: SCGP00525)

20. Snap-seal disposable plastic sample containers (CorningTM, catalog number: 1730-10)

Equipment

1. Computer (PC) running up-to-date Windows operating system (any)

2. Micro mill (CNC Mini-Mill/GX, Minitech, catalog number: CNC Mini-Mill/GX)

3. Shop vacuum (12 Gallon 5.0 Peak HP NXT wet/dry shop vacuum with filter, locking hose and accessories (The Home Depot, catalog number: 1002916304)

4. Pressurized air source (ALPHAGAZTM 1 Grade Nitrogen, Size 300 High Pressure Steel Cylinder, CGA 580) (Airgas, catalog number: NI AZ1300SMT)

5. Gram scale (Uline Balance Scale, ULINE, catalog number: H-9884)

6. Orbital mixer (Orbital mixer, FlackTek, Inc., catalog number: Speedmixer DAC 150.1 FVZ-K)

7. Vacuum desiccator (NalgeneTM Transparent Polycarbonate Classic Design Desiccator, ThermoFisher, catalog number: 5311-0250PK)

8. Oven (65 °C) (Heratherm General Protocol Oven, ThermoFisher, catalog number: 51028112)

9. Oven (120 °C) (Heratherm General Protocol Oven, ThermoFisher, catalog number: 51028112)

10. 500 μm square carbide end mill (TR SERIES 2 FLUTE MICRO END MILLS ≤ 0.0600, Performance Micro Tool, catalog number: TR-2-0200-S)

11. 100 μm ball nose carbide end mill (TR SERIES 2 FLUTE MICRO BALL END MILL, Performance Micro Tool, catalog number: TR-2-0040-BN)

12. Plasma oxidizer (Tergeo plasma cleaner, Pic Scientific)

13. Certified chemical fume hood (60″ Lab Fume Hood Vertical Sash, CleaTech, catalog number: SKU 1100-3-B)

14. Hotplate with magnetic stirring (USA Lab Hotplate Stirrer 380, 5L, TUV Certified, USALAB, catalog number: SKU: USA-H380-PRO)

15. Laser thermometer (REED INSTRUMENTS Infrared Thermometer: R2300, Max Temp/Min Temp, Adj @ 0.10 to 1.00, Full Size Body, Grainger, catalog number: R2300)

16. Pipette aid (Drummond DP-101 Portable Pipet Aid XP Pipette Controller, 110V, Pipette.com, SKU: DP-101)

17. pH probe (Ohaus ST2200-F Benchtop pH Meter Kit, Hogentogler, catalog number: SKU ST2200-F)

18. Refrigerated tabletop centrifuge (SorvallTM ST 16 Centrifuge Series, ThermoFisher, catalog number: 75004380)

19. Inverted brightfield microscope (DMi1 Inverted Microscope, Leica Microsystems, catalog number: 11526231)

20. Band saw (JET JT9-708115K Model JWBS-14CS 1HP 1-Phase 115/230V 14" Closed Stand Bandsaw, Global Industrial, Model: WBB57825)

21. Cell culture incubator (BB15 CO2 Incubator, ThermoFisher, catalog number: 51023121)

22. Hemocytometer or cell counter (Cellometer Auto T4 Bright Field Cell Counter, Revvity, catalog number: CMT-AT4P)

23. Vortexer (Original Vortex Genie 2, Pipette.com, catalog number: 00-SI-0236)

24. Micropipettes (Gilson PIPETMAN Neo Pipette Set, Gilson, catalog number: GNPST)

25. LN2 tank (Locator 6 Rack and Box System, ThermoFisher, catalog number: CY50985)

26. BSC class II (1300 Series Class II, Type A2 Biological Safety Cabinet Packages, 120 V 50/60 Hz, ThermoFisher, catalog number: 1323TS)

Software and datasets

1. SolidWorks 2025 by SolidWorks (https://www.solidworks.com/)

2. Mach Mach3 3.043.066 by ArtSoft (https://www.machsupport.com/software/mach3/)

3. Fusion v.2.0.19941 by AutoDesk (https://www.autodesk.com/products/fusion-360/overview)

Procedure

文章信息

稿件历史记录

提交日期: May 17, 2025

接收日期: Aug 28, 2025

在线发布日期: Sep 7, 2025

出版日期: Oct 5, 2025

版权信息

© 2025 The Author(s); This is an open access article under the CC BY license (https://creativecommons.org/licenses/by/4.0/).

如何引用

Viola, H. L., Vasani, V. and Takayama, S. (2025). A Protocol Guide to Micro Milling for Bio-Microfluidics. Bio-protocol 15(19): e5459. DOI: 10.21769/BioProtoc.5459.

分类

生物工程 > 生物医学工程

您对这篇实验方法有问题吗?

在此处发布您的问题,我们将邀请本文作者来回答。同时,我们会将您的问题发布到Bio-protocol Exchange,以便寻求社区成员的帮助。

Share

Bluesky

X

Copy link