- Submit a Protocol

- Receive Our Alerts

- Log in

- /

- Sign up

- My Bio Page

- Edit My Profile

- Change Password

- Log Out

- EN

- EN - English

- CN - 中文

- Protocols

- Articles and Issues

- For Authors

- About

- Become a Reviewer

- EN - English

- CN - 中文

- Home

- Protocols

- Articles and Issues

- For Authors

- About

- Become a Reviewer

Purification of Crimean Congo Hemorrhagic Fever Virus (CCHFV) Nucleocapsid Protein Using Detergent Gradient and Free Thawing

Published: Vol 12, Iss 15, Aug 5, 2022 DOI: 10.21769/BioProtoc.4483 Views: 1988

Reviewed by: Alessandro DidonnaNimesha TadepalleAnonymous reviewer(s)

Protocol Collections

Comprehensive collections of detailed, peer-reviewed protocols focusing on specific topics

Related protocols

Expression and Ni-NTA-Agarose Purification of Recombinant Hepatitis C Virus E2 Ectodomain Produced in a Baculovirus Expression System

Julián Gómez-Gutiérrez [...] Belén Yélamos

Oct 5, 2018 6509 Views

Assay to Study the Phase-transition Behavior of Edc3, a Conserved Processing Body (P-body) Marker Protein

Raju Roy and Purusharth I. Rajyaguru

Aug 20, 2022 3193 Views

Carbamoyltransferase Enzyme Assay: In vitro Modification of 5-hydroxymethylcytosine (5hmC) to 5-carbamoyloxymethylcytosine (5cmC)

Weiwei Yang [...] Laurence Ettwiller

Sep 5, 2022 2015 Views

Abstract

Protein aggregation remains a major challenge in the purification of recombinant proteins in both eukaryotic and prokaryotic expression systems. One such protein is the nucleocapsid protein of Crimean Congo Hemorrhagic fever virus (CCHFV), which has high aggregation tendency and rapidly precipitates upon purification by NiNTA chromatography. Using the detergent gradient purification approach reported here, the freshly purified protein by NiNTA chromatography was mixed with the dilution buffer containing a high detergent concentration, followed by overnight freezing at -80 °C. Thawing the resulting mixture at room temperature triggered the formation of a detergent concentration gradient containing the active protein in the low detergent concentration zone towards the top of the gradient. The inactive aggregates migrated to the high detergent concentration zone towards the bottom of the gradient. The method prevented further aggregation and retained the activity of the native protein despite numerous freeze–thaw cycles. This simple approach creates an appropriate microenvironment towards the top of the gradient for correctly folded proteins, and it prevents aggregation by rapidly separating the preformed early aggregates from the correctly folded protein in the mixture. This unique approach will be of potential importance for the biotechnological industry, as well as other fields of protein biochemistry that routinely purify recombinant proteins and face the challenges of protein aggregation.

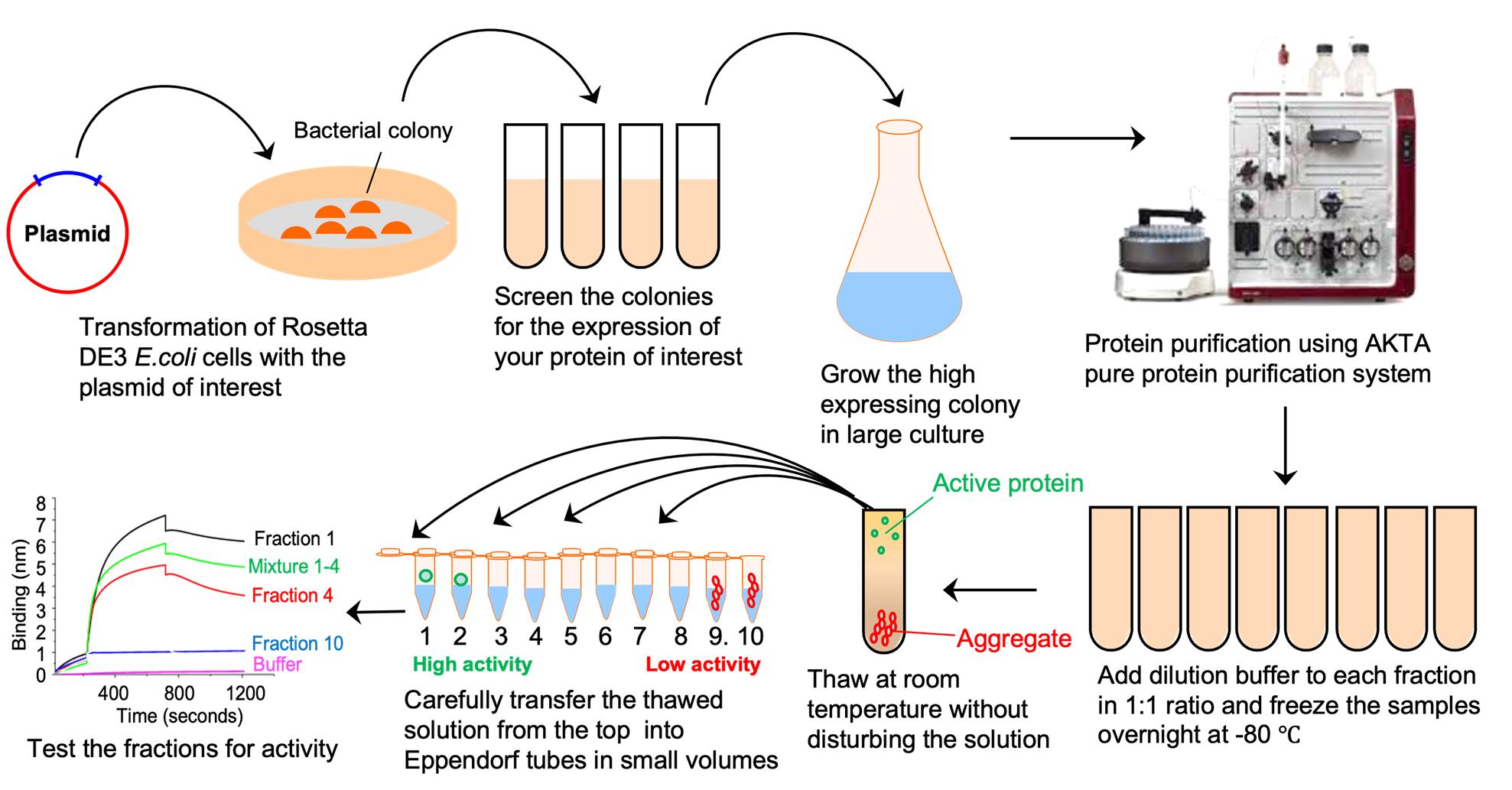

Graphical abstract:

Background

Expression and purification of recombinant proteins from bacterial, viral, and eukaryotic expression systems is routinely carried out in the biotechnological industry, especially in the areas of development and commercialization of successful protein-based drug products. In addition, the expression and purification of recombinant proteins to study protein-protein, protein-nucleic acid, and protein-drug interactions, is routinely carried out in both academic institutions and the biotechnological industry. The inherent high aggregation tendency of proteins at various stages of expression, purification, and storage has significant impact upon product quality, safety, and efficacy. Unlike eukaryotes, the reduced environment of the bacterial cytosol and the lack of eukaryotic chaperones and post-translational machineries limit the efficient protein folding capability of a bacterial system. Due to these limitations, the huge expression of recombinant proteins in Escherichia coli (E. coli) often results in aggregation in inclusion bodies (Williams et al., 1982; Freedman and Wetzel, 1992; Chrunyk et al., 1993). The expression of the recombinant proteins at high translational rates exhausts the bacterial protein quality control system, resulting in the aggregation of partially folded and misfolded protein molecules to form inclusion bodies (Carrio and Villaverde, 2005). Formation of inclusion bodies poses a great challenge in the production and purification of recombinant proteins using E. coli as host. Purification of native-like proteins from inclusion bodies is extremely difficult. Despite the intensive processing, including the isolation of inclusion bodies from the cell, solubilization using denaturants, followed by refolding, the finally purified proteins tend to re-aggregate and show minimal activity. Protein aggregation in inclusion bodies can be reduced by decreasing the temperature of growing bacterial culture up to 16°C and reducing the inducer concentration. Although these efforts can be helpful for certain proteins, for most others the aggregation is triggered when bacterial cells are lysed during the purification process.

The detergent gradient approach discussed here for the purification of Crimean Congo Hemorrhagic fever virus (CCHFV) nucleocapsid protein (CCHFVNP) separates the early formed inactive protein aggregates from the correctly folded active protein and prevents further aggregation in the native protein sample. The correctly folded protein is retained in the appropriate microenvironment of the gradient, making the protein resistant to aggregation, despite numerous freeze–thaw cycles. The approach can be customized for the purification of any recombinant protein that is prone to aggregation. This native protein purification method produces a significant amount of pure protein without denaturation and refolding steps, commonly used in most protein purification procedures. The yield of the active protein produced by this method depends upon the aggregation tendency of the protein, which varies from protein to protein. If a protein has more aggregation tendency, the aggregates will move towards the bottom of the gradient, and little active protein stays on the top. For our protein (CCHFNP), almost 60% was aggregated, and the remaining 40% was active, which was pooled together and stored for later use. The approach will be of potential significance to the biotechnological industry, which faces challenges of protein aggregation at different stages of development and commercialization of protein-based drug products (Wang and Roberts, 2018).

Materials and Reagents

Toothpicks

Bacterial cultural tubes (MTC BIO, catalog number: T8235)

15 mL tubes (VWR, catalog number: 525-1070)

0.5 mL microtubes, black DNase RNase free (ARGOS, catalog number: T7456-001)

Plasmid pET-30a and Plasmid pET-CCHFNP

Triton X-100 (Fisher Bioreagents, catalog number: BP151-500)

HisTrap FF crude (Cytiva, catalog number: 17528601)

High Precision Streptavidin (SAX) (ForteBio, catalog number: 18-0037)

Rosetta (DE3) Competent Cells (Millipore Sigma, catalog number: 70954)

Kanamycin sulfate (Fisher Scientific, catalog number: BP906-5)

IPTG (IBI Scientific, catalog number: IB02125)

Protein ladder (Fisher Scientific, catalog number: 26616)

HisTrap FF crude (Cytiva, catalog number: 17528601)

Fraction collector F9-R (GE Healthcare, catalog number: 29011362)

T7 RNA polymerase kit (Promega, catalog number: P1300)

Biotin-11-CTP (Perkin Elmer, catalog number: NEL542001EA)

Bradford Protein Assay Kit 4 (Bio Rad, catalog number: 5000204)

1,000× Kanamycin stock (see Recipes)

1,000× IPTG stock (see Recipes)

Lysis buffer (see Recipes)

Elution buffer (see Recipes)

LB Broth (see Recipes)

LB Agar Plates (see Recipes)

5× SDS Loading Dye (see Recipes)

SDS-PAGE (see Recipes)

Coomassie Blue Staining solution (see Recipes)

Coomassie Blue Destaining solution (see Recipes)

Biotinylated RNA (see Recipes)

Dilution buffer (see Recipes)

RNA Binding Buffer (see Recipes)

Equipment

Spectrophotometer (Jenway, model: 6705; absorbance wavelength range 190–1,100 nm)

BLITZ probe (Nemko, forteBIO, model: BLITZ)

HPLC AKTA Pure 25L (GE Healthcare, Cytiva, model: 29018224)

Isotemp Incubator (Fisher Scientific, catalog number: 11-690-637D)

Excella E24 Incubator Shaker Series (New Brunswick Scientific, model: M1352-0000)

Allegra X-14R Centrifuge (Beckman Coulter)

Sonicator-Sonic Dismembrator Model 100 (Fisher Scientific, model: XL2000-350)

Legend Micro 17 Centrifuge (Sorvall, Thermo Scientific)

SDS-PAGE gel running system (Bio-Rad)

Software

Unicorn 7 (Cytiva)

BlitzPro 1.2 (ForteBio)

Procedure

Transformation of the plasmid in Rosetta DE3 E. coli cells

The gene encoding the CCHFV nucleocapsid protein (CCHFVNP) was synthesized by GenScript and cloned between NdeI and XhoI restriction sites in a pET-30a (+) backbone. The resulting plasmid (pET-CCHFNP) was obtained as a lyophilized powder from GenScript, and dissolved in Molecular Biology grade water at a final concentration of 20 ng/µL. This plasmid expresses CCHFVNP containing a C-terminal 6X His-tag. Alternatively, the plasmid can be generated in your own lab. Any inducible vector expressing the His-tagged protein of interest in bacteria can be used.

Thaw a vial of competent Rosetta (DE3) cells (~75 µL) on ice, and add 5 µL of the pET-CCHFNP plasmid (20 ng/µL) to the vial, followed by incubation of the resulting mixture on ice for 30 min.

Transfer the vial to a water bath at 30 °C for 1.5 min, and immediately incubate on ice for 2 min.

Add 700 µL of fresh LB broth to the mixture, and agitate the cells at 250 rpm using a bacterial shaker incubator at 37 °C for 90 min.

Carefully spread 100 µL of the transformed Rosetta cells onto an agar plate containing kanamycin (50 µg/mL). See the Recipes section for pouring agar plates.

Invert the plate and incubate inside a bacterial incubator at 37 °C overnight.

Screening bacterial colonies for protein expression

The next morning, identify five isolated colonies and label them as colonies 1, 2, 3, 4, and 5 on the backside of the agar plate. Lift the five isolated colonies from the agar plate one by one using a sterile toothpick. Drop each toothpick into a culture tube containing 5 mL of LB media with kanamycin (50 µg/mL).

Incubate each tube with constant shaking (250 rpm) inside the shaker incubator at 37 °C overnight.

The next morning, make up two 5-mL tubes of fresh LB media containing kanamycin (50 µg/mL) for each overnight culture tube. You will end up making a total of ten fresh LB tubes for five overnight culture tubes. Add 50 µL of the overnight culture from colony 1 to two tubes and label them properly to represent colony 1. This way, you will generate two secondary cultures for each colony, using the primary overnight culture. Repeat the process for colonies 2, 3, 4, and 5. Save the remaining primary overnight cultures at 4 °C for future inoculations.

Incubate the ten freshly made secondary cultures with constant shaking (250 rpm) at 37 °C for 2–3 h, and periodically keep checking the OD at 600 nm using a spectrophotometer. When the OD600 reaches 0.3–0.5, remove the tubes from the incubator. It usually takes 3–5 h to reach an OD of 0.3–0.5 at 600 nm.

Add 5 µL of IPTG stock solution (1,000×) to one of the two tubes of secondary culture for each colony. Do not add IPTG to the other tube, as this will be used as control later.

Incubate all tubes with constant shaking at 250 rpm at 16 °C overnight.

Transfer the overnight secondary cultures to fresh 15-mL tubes and pellet the cultures down by centrifugation at 4,000 × g and 16 °C for 15 min. Discard the supernatant, and save the bacterial pellets.

Add 80 µL of lysis buffer to each pellet, and vortex until the pellet becomes dispersed. Transfer the lysate into a 1.5-mL Eppendorf tube, and, using a sonicator, sonicate the mixture at 40 kHz (>400W) on ice for 5 min. Add 20 µL of 5× SDS loading dye to each tube. Load 15 µL of the resulting solution into a 12% SDS-PAGE gel. Load 10 µL of protein ladder in one of the lanes. Run the gel at 100 V until the dye front has passed the stacking gel, after which the voltage can be increased up to 200 V, if you want to save time. Stop running the gel when your protein of interest has reached the middle of the resolving gel, determined by looking at the marker lane.

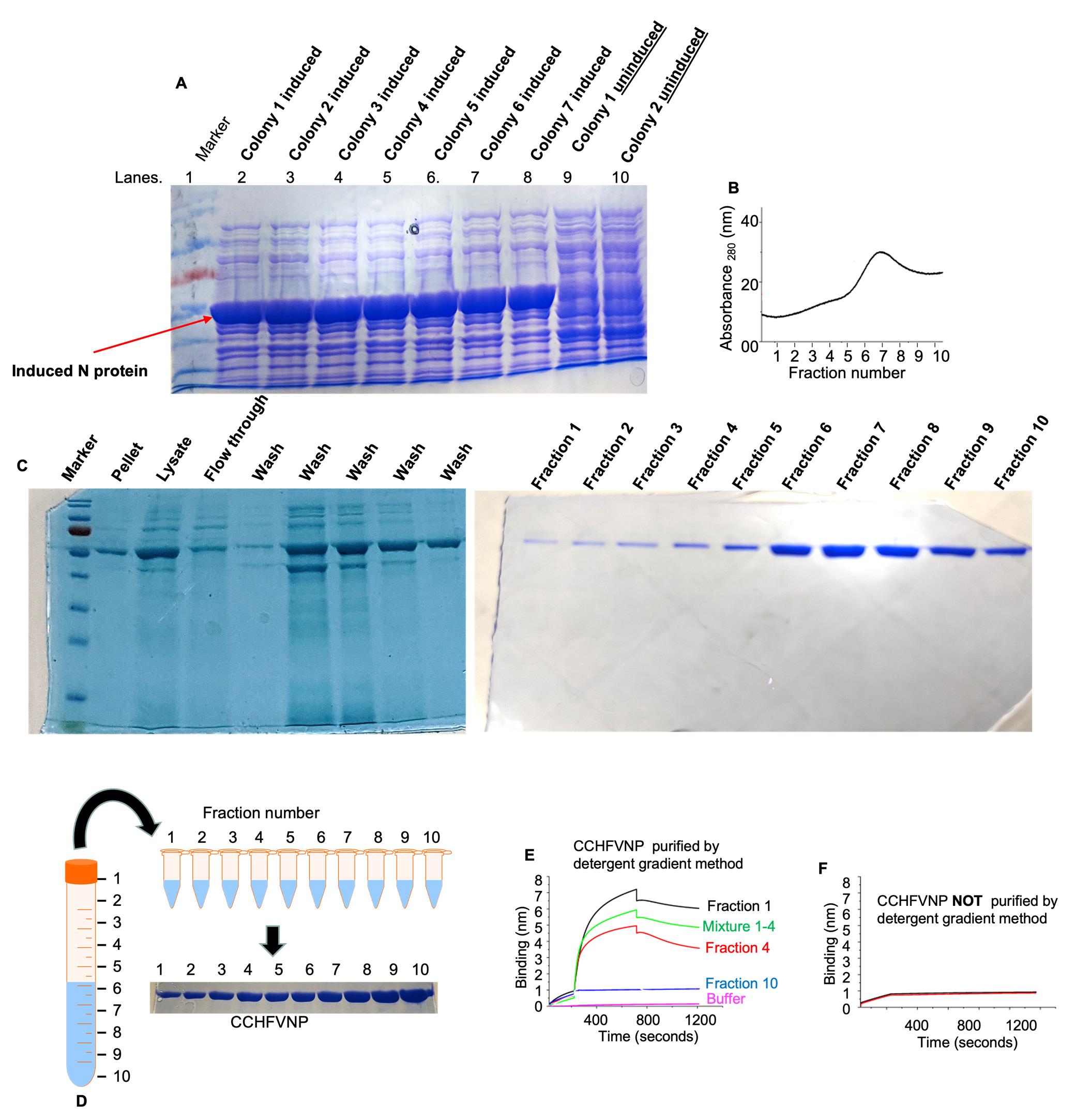

Transfer the gel into a small box containing 200 mL of coomassie blue staining solution and keep on the rocker at room temperature for 1 h. Remove the gel from the staining solution and wash three times with 5–10 mL of water. Transfer the washed gel into 200 mL of destaining solution and keep on the rocker at room temperature for 1 h. If the bands are not visible, then add fresh destaining solution, and incubate the gel again until bands are visible. Compare the intensity of your band of interest between induced and uninduced lanes. The clear difference between induced and uninduced samples will help identify the colony that shows the best expression after induction. For example, a clear difference is noticed in the N protein band intensity, between induced and uninduced cells in Figure 1A (compare the induced lanes 2 and 3 with the corresponding uninduced lanes 9 and 10 in Figure 1A). Select the best expressing colony for large-scale expression.

Once the colony expressing the highest amount of protein has been identified, take 1 mL of the primary culture from that colony, saved at step 9, and add it to 500 mL of LB media containing kanamycin (50 µg/mL). Start this step in the morning.

Incubate the resulting culture with shaking at 37 °C, periodically measuring OD of the culture solution at 600 nm, as mentioned in step 10.

When the OD at 600 nm reaches 0.3–0.5, add 500 µL of the IPTG stock solution (1,000×), followed by incubation with constant shaking at 16 °C overnight, as mentioned in step 12.

The next morning, divide the 500 mL of overnight culture into five tubes, and pellet each tube down by centrifugation at 4,000 × g for 20 min. Discard the supernatant, and save the pellets to be used for protein purification in the next step. Alternatively, the pellets can be stored at -80 °C for later use.

Purification of CCHF-NP using the AKTA pure machine.

Resuspend the pellet from a single tube from step 19 in 20 mL of lysis buffer. Sonicate the lysate six times, for a period of 30 s each, resting the sample on ice for 60 s in between sonication steps. The sonication intensity level is set to ultrasonic frequency -40 kHz (>400W) on the sonicator. However, any other sonicator with ultrasonic frequency >20 kHz can be used for the sonication of cell lysates.

The culture should become noticeably clearer after sonication but will still be somewhat opaque. If the lysate is not clear, you can sonicate at an intensity level of 4 for an additional 30 s, resting the solution on ice for 1 min.

Centrifuge the lysate at 4,300 × g for 20 min to pellet down the cell debris. Store the pellet at -80 °C for later use to confirm that a significant amount of the protein was solubilized into the supernatant. The supernatant will be used in step 23 below. Reserve 100 µL of the supernatant for SDS-PAGE at a later step.

Prepare 500 mL of each lysis buffer and elution buffer in two separate beakers, labeled as beaker A and Beaker B, respectively. Load the supernatant from step 22 into the super loop of the AKTA Pure HPLC protein purification system, and a total of 20 mL of both lysis and elution buffers in equal ratio at the full speed of 20 mL per min. This will clean the pumps and tubing of the AKTA Pure system, and the outflow will go to waste as default.

Attach the HisTrap column to the AKTA Pure protein purification system. Using the Unicorn 7.0 software, equilibrate the column with the lysis buffer by running at least 10 column volumes through the column, at a speed of 4.0 mL per min. Ensure the pressure on the column never exceeds 0.5 Mpa.

While the column equilibrates, prepare the run program on the Unicorn 7.0 software, as follows:

Wash the column with 5 column volumes (5 CV) of lysis buffer.

Reset the UV monitor to zero.

Add the sample to the column at a speed of 1 mL/min. Collect the flowthrough.

Wash the column with 5 CV of lysis buffer. Collect the washes using the fraction collector.

Run the elution gradient from 0% elution buffer to 100% elution buffer over 20 CV. Collect the fractions using the fraction collector.

Wash the column with 10 CV of elution buffer. Let the washes go to waste.

Wash the column with 10 CV of water. For long-term storage, use 20% ethanol in water.

Start the run and pick up the samples from the fraction collector when the run is complete. If your protein has high aggregation tendency, you may see the solution turning turbid at this stage. Under such circumstances, quickly follow steps 27 and 28 below.

Use the elution profile saved on the AKTA purifier to identify the fractions containing the eluted protein. As shown in Figure 1B, the CCHFVNP starts eluting from fraction 1 and peaks in fraction 7. Save 100 µL of sample from each elution at -80 °C for SDS-PAGE analysis to confirm the presence of the protein in the eluted fractions.

Add an equal volume of dilution buffer to each eluted fraction. Gently mix the solution, and freeze the tubes upright at -80 °C overnight.

Figure 1. Purification of CCHFV nucleocapsid protein using a detergent gradient approach. (A) Coomassie-stained 12% SDS-PAGE gel, showing the CCHFV NP expression in different colonies of Rosetta DE3 E. coli cells. Uninduced colonies 1 and 2 are shown as control. (B) The elution profile of CCHFVNP from AKTA pure protein purification system. (C) Coomassie-stained 10% SDS-PAGE gel, showing the CCHFVNP in representative elution fractions from the AKTA pure. (D) The diluted fraction containing a total of 10 mL of solution is thawed at room temperature, after overnight freezing at -80 °C. The numbers on the line show the 1-mL markings on the tube. Pour the 1-mL fractions from the 10-mL tube into 1.5 mL-Eppendorf tubes, without disturbing the concentration gradient, as shown. SDS-PAGE analysis of the 1.5-mL fractions shows the presence of CCHFVNP in each fraction. (E) Fractions 1, 4, 10, and a mixture of fractions 1–4 from panel D were assayed for RNA binding activity using BLI. (F) RNA binding analysis of CCHFVNP using BLI. It should be noted that the CCHFVNP used in panel F was not purified by detergent gradient as shown in panel D. No RNA binding activity was observed. This data has been published in our recent manuscript (Royster et al., 2021).The next morning, run the saved fractions from step 27 on a 12% SDS-PAGE gel, to identify the fractions that contain the highest concentration of pure protein devoid of any contaminating bacterial protein. Stain the gel with Coomassie blue, followed by destaining, as mentioned in steps 13 and 14. As shown in Figure 1C, the contamination-free CCHFVNP is present in all eluted fractions. However, the concentration is highest in fractions 6–8. It may happen that some elutions still contain contaminant bacterial protein—those fractions should be avoided.

Optional: Running a sample from the original lysate (step 22), flowthrough (step 25c), and pellet (step 22) helps to determine whether the protein is soluble in the lysate, and if the soluble protein can bind the column efficiently. As shown in Figure 1C, the CCHFVNP is soluble in lysis buffer, but a good amount of the protein still remains in the pellet. The protein binds tightly to the column, as a small amount is present in the flowthrough.

Once the fractions containing high concentrations of the protein devoid of contamination are identified in step 29, take out the corresponding diluted fractions from the -80 °C freezer (from step 28). For example, as shown in Figure 1C, the highest concentration of CCHFVNP is present in fractions 6–8, so the diluted fraction 7 is taken out from the -80 °C freezer. The fractions are allowed to thaw undisturbed upright at room temperature. While the solutions thaw, a detergent gradient is formed, with high concentration of the detergent at the bottom of the tube, and low detergent concentration at the top of the tube. The misfolded proteins migrate towards the high detergent concentration, towards the bottom of the tube. The correctly folded proteins remain in the low concentration zone, towards the top of the gradient. Never disturb the thawed tube, as it disturbs gradient formation.

Carefully remove 1-mL fractions from the top of the thawed tube using a pipette, aspirating gently and avoiding expelling air bubbles into the tube. Pour the aspirated 1-mL fraction into a 1.5-mL Eppendorf tube, as shown in Figure 1D. Top fractions will contain correctly folded protein, and misfolded protein will be present in the bottom fractions. Quantify the protein in each fraction using the Bradford Protein Assay Kit. The protein fractions can be stored in the -80 °C freezer. The fractions containing the active protein can be pooled together for long-term use. For our protein (CCHFNP), almost 60% was aggregated, and the remaining 40% was active.

Testing the RNA binding activity of the protein in detergent gradient fractions using Biolayer interferometry (BLI).

Add 5 µL of the biotinylated RNA (1.2 µg/µL) to 300 µL of RNA binding buffer, and save the resulting mixture in a black 0.5-mL Eppendorf tube on ice.

Program the BLITZ PROBE (ForteBio) machine, using the inbuilt BlitzPro 1.2 Software.

Select the initial wash step with RNA binding buffer for 30 s.

Select the binding of biotinylated RNA to the Biosensor for 200 s.

Select the second wash step with RNA binding buffer for 30 s.

Select the association of the protein to the biotinylated RNA for 300 s.

Select the dissociation of protein from the RNA for 500 s.

Hydrate the High Precision Streptavidin biosensor in RNA binding buffer for at least 10 min. Load the hydrated probe into the BLITZ machine.

Dilute the protein from fraction 1 at the required concentration in RNA binding buffer inside a 0.5-mL black tube. Keep the RNA binding buffer ready for wash steps. Do not dilute the protein before, to avoid potential aggregation. Start the run. The software will guide you following the instructions from step 34. As the binding cycle is running, the binding data is consecutively plotted by the inbuilt software, as shown in Figure 1E. After the completion of the first cycle, start another cycle with different concentration of the same protein fraction, but keep the concentration of the RNA same (1.2 µg/µL).

Once the kinetic curves at two or more concentrations of each fraction have been obtained, the kinetic data is analyzed by the BlitzPro 1.2 Software, to calculate the on-rate and off-rate constants, which are then used by the software to calculate the dissociation constant (Kd) that quantifies the binding affinity of the protein-RNA interaction.

Examine all other fractions of the detergent gradient to identify the fractions that contain the active protein, as shown by representative curves in Figure 1E. We plotted the binding curves of CCHFVNP before its purification by the detergent gradient approach, to demonstrate that it did not show activity (Figure 1F).

Data analysis

Generate the kinetic profiles for the protein-RNA interaction, also referred as sensograms, at a fixed concentration of the RNA and two or more concentrations of the protein, as shown in Figure 1E. The kinetic profiles are then analyzed by the inbuilt Blitz Pro 1.2 software in the global mode, in which all the sensograms at different concentrations are processed by the software to generate an on-rate constant (Kass), and an off-rate constant (Kdis). The software then uses these constants to calculate the dissociation constat (Kd). Note that Kd = Kass/Kdis. The sensograms are then individually analyzed by the Blitz Pro1.2 software in the local mode, to calculate these parameters for each sensogram. If the experiment is carried out at three different concentrations of the protein, then three sensograms will generate three Kd values, which are used to calculate the standard deviation (SD), as shown below.

Table 1. Binding parameters for the association of wild-type N protein and its stalk domain with the 5’ UTR of S-segment derived mRNA

| Protein Name | Kd (nM) | Kass (m-1 s-1) | Kdis (s-1) |

| Stalk Fraction 1 | 54.24 ± 10 | 1.08 × 105 | 5.87 × 10-3 |

| Stalk Fraction 4 | 52.48 ± 16 | 3.11 × 105 | 1.82 × 10-2 |

| Stalk Mixture 1–4 | 36.67 ± 3 | 1.40 × 105 | 5.10 × 10-3 |

Recipes

1,000× kanamycin stock

Reagent Final concentration Amount Kanamycin 50 mg/mL 0.5 g H2O n/a 10 mL Total n/a 10 mL Before adding the antibiotic to LB agar, first autoclave the LB solutions, and then allow them to cool to ~40 °C before adding the antibiotic.

1,000× IPTG stock

Reagent Final concentration Amount IPTG 0.5 M 1.2 g H2O n/a 10 mL Total n/a 10 mL Lysis buffer

Reagent Final concentration Amount NaCl 150 mM 17.5 g Tris-HCl (pH 7.4) 50 mM 12 g Triton X-100 1% 20 mL H2O n/a 1,980 mL Total n/a 2,000 mL To maintain ideal binding efficiency with the Ni2+ column, this buffer should have a pH 7.2–8.0.

Elution buffer

Reagent Final concentration Amount NaCl 500 mM 29 g Tris-HCl (pH 7.0) 50 mM 6 g Imidazole 250 mM 17g Triton X-100 1% 10 mL H2O n/a 990 mL Total n/a 1,000 mL LB Broth

Reagent Final concentration Amount LB Miller Broth 2.5% 25 g H2O n/a 1 L Total n/a 1 L Autoclave immediately after mixing, and allow to cool to touch before adding any antibiotics.

LB Agar Plates

Reagent Final concentration Amount LB Miller Agar 4% 40 g H2O n/a 1 L Total n/a 1 L Autoclave immediately after mixing, and allow to cool to touch before adding any antibiotics. Add antibiotics when agar is approximately 60 °C, then mix and pour immediately.

5× SDS Loading Dye

Reagent Final concentration Amount Tris-HCl 250 mM 4.4 g SDS 10% 30 g Glycerol 30% 90 mL B-Mercaptoethanol 5% 15 mL Bromophenol blue 0.02% 60 mg H2O n/a 195 mL Total n/a 300 mL β-Mercaptoethanol should be added to aliquots of SDS dye, as it is not stable at room temperature.

SDS-PAGE

Reagent 5% stacking gel Resolving gel 12% Ultrapure H2O 4.0 mL 3.3 mL 30% bis-Acrylamide 1.0 mL 4.0 mL 1 M Tris-HCl, pH 6.8 0.75 mL NA 1.5 M Tris-HCl, pH 8.8 NA 2.5 mL 10% SDS 60 µL 100 µL 10% APS 60 µL 100 µL TEMED

Total volume

8 µL

6 mL

8 µL

10 mL

Volumes given are sufficient for making two gels in 1.00 mm plates. Make and pour the resolving gel first. Add 1 mL of either ethanol or isopropanol on top of the resolving gel. After 15–20 min, when the resolving gel has set, pour out the sealing fluid. Make and pour the stacking gel directly on top of the resolving gel and insert the comb.

Coomassie Blue Staining solution

Reagent Final concentration Amount Methanol 50% 250 mL Glacial Acetic Acid 10% 50 mL Coomassie Blue 0.125% 0.625 g H2O n/a 200 mL Total n/a 500 mL Coomassie Blue Destaining solution

Reagent Final concentration Amount Methanol 40% 200 mL Glacial Acetic Acid 10% 50 mL H2O n/a 250 mL Total n/a 500 mL Biotinylated RNA

The 40-nucleotide long RNA, corresponding to the 5’ end of viral S-segment genomic RNA, is synthesized by Genscript and labeled at 3’ with biotin. Alternatively, the RNA can be synthesized using T7 RNA polymerase kit, and Biotinylated with CTP. The RNA is dissolved in RNase free water at a concentration of 1.2 μg/μL, and stored in 5-μL aliquots inside the -80 °C freezer.

Dilution buffer

Reagent Final concentration Amount Tris-HCl (pH 7.4) 50 mM 6 g L-Arginine 2 mM 0.35 g L-Glutamine 2 mM 0.30 g Triton X-100 1% 10 mL Tween 20 0.4% 4 mL H2O n/a 986 mL Total n/a 1,000 mL RNA Binding Buffer

Reagent Final concentration Amount NaCl 80 mM 2.3 g HEPES (pH 7.4) 40 mM g KCl 20 mM 0.8 g DTT 1 mM 0.08 g H2O n/a 500 mL Total n/a 500 mL

Acknowledgments

We would like to thank Dr. Mohammad Mir for reviewing this protocol. The Data (Figure 1) reported in this protocol has been previously published (Royster et al., 2021).

Competing interests

The authors do not have any financial or non-financial competing interests.

References

- Carrio, M. M. and Villaverde, A. (2005). Localization of chaperones DnaK and GroEL in bacterial inclusion bodies.J Bacteriol 187(10): 3599-3601.

- Chrunyk, B. A., Evans, J., Lillquist, J., Young, P. and Wetzel, R. (1993). Inclusion body formation and protein stability in sequence variants of interleukin-1 beta. J Biol Chem 268(24): 18053-18061.

- Freedman, R. B. and Wetzel, R. (1992). Protein engineering. Curr Opin Biotechnol 3(4): 323-325.

- Royster, A., Mir, S. and Mir, M. A. (2021). A novel approach for the purification of aggregation prone proteins.PLoS One 16(11): e0260143.

- Wang, W. and Roberts, C. J. (2018). Protein aggregation - Mechanisms, detection, and control. Int J Pharm 550(1-2): 251-268.

- Williams, D. C., Van Frank, R. M., Muth, W. L. and Burnett, J. P. (1982). Cytoplasmic inclusion bodies in Escherichia coli producing biosynthetic human insulin proteins. Science 215(4533): 687-689.

Article Information

Copyright

© 2022 The Authors; exclusive licensee Bio-protocol LLC.

How to cite

Royster, A. and Mir, S. (2022). Purification of Crimean Congo Hemorrhagic Fever Virus (CCHFV) Nucleocapsid Protein Using Detergent Gradient and Free Thawing. Bio-protocol 12(15): e4483. DOI: 10.21769/BioProtoc.4483.

Category

Biochemistry > Protein > Isolation and purification

Biological Engineering > Biomedical engineering

Do you have any questions about this protocol?

Post your question to gather feedback from the community. We will also invite the authors of this article to respond.

Share

Bluesky

X

Copy link